Why is ULM II the best gas suit on the market?

TheULM II is one of MATISEC's benchmark products for the protection of men and women working in hostile environments. On the market for 3 years, it is the flagship product in gas-tight chemical protection suits. It has a number of features that make it the best "normal robustness" chemical suit on the market. In this article, we'll look at the technical features and strengths of this product, which is used in a wide range of applications (trades, types of intervention).

ULM II, high-performance, high-quality chemical protection

In an environment where the safety of response teams is paramount, choosing the right protective equipment is essential. With this in mind, we have designed and developed theULM II, an innovative product that meets the strict requirements of European regulation 2016/425 on personal protective equipment (PPE).

ULM II complies with EN 943-1 and EN 943-2, the standards governing gas-tight chemical protective clothing. These standards distinguish garments according to their level of robustness: "normal" and "reinforced".ULM II falls into the category of " normal strength" garments, offering an ideal compromise between performance, cost of ownership and maintenance costs.

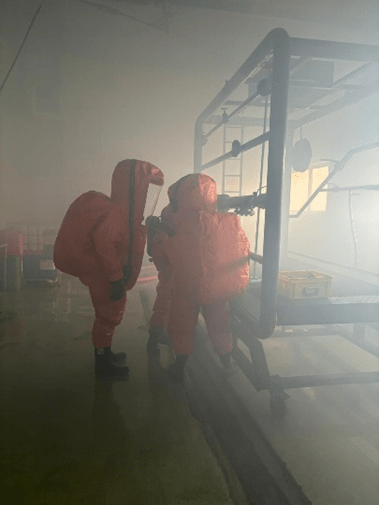

ULM II is a type 1a-ET encapsulated suit with an Insulated Breathing Apparatus (IBA) inside the suit, for use by emergency response teams. It is tested to EN 14126 standard, providing effective protection against biological agents such as bacteria and viruses, making it ideal for use in medical, industrial and health crisis management environments.

The ULM II suit also complies with the EN 1073-2 standard, which guarantees protection against radioactive contamination. The garment is able to limit the wearer's exposure to radioactive particles in nuclear or radiological risk environments.

MC3 complex, the main material of ULM II, has been tested to EN 1149-3 for the measurement of electrostatic charge attenuation, the test method of EN 1149-5. This additional test guarantees that the material is capable of dissipating accumulated electrostatic charges. This material is also tested according to the Finabel 0.7.C label, which determines its resistance to war toxins. This standard is adopted mainly by European armed forces to certify protective equipment for nuclear, radiological, biological and chemical (NRBC) environments. This enables us to guarantee the operational reliability of our combination for military or civilian use in NRBC scenarios.

ULM II chemical protective clothing is comprehensive, versatile and compliant with the most stringent industry standards. It covers a wide range of risks, from chemical and biological hazards to radioactive particles and electrostatic discharge. The ULM II is suitable for use by intervention teams in extreme industrial, civil and military conditions.

It ensures the wearer's safety in a variety of scenarios. It is widely used in the following sectors:

- Fire and rescue

- Military, defense and CBRN

- Pharmaceuticals and laboratories

- Food industry

- Chemicals and petrochemicals

ULM II, a combination with many strengths

- The best mechanical strength on the market

ULM II has the highest mechanical strength of any normal-strength combination on the market. At MATISEC, we develop our own laminates in order to control and guarantee the highest performance for our solutions over the long term.

ULM II is assembled with MC3 material composed of ATG barrier film laminated to a non-woven backing. ATG is an ultra-thin barrier film with 14 layers, guaranteeing superior chemical protection.

- High chemical resistance

ULM II's chemical resistance is high thanks to two layers of ATG barrier film, rated 6/6 out of 15 chemicals in EN 943-2. ULM II is also tested against other industrial chemicals, including 6 warfare agents according to the Finabel 0.7 standard, such as mustard (HD), Sarin (GB), VX, Tabun (GA), Soman (GD), and Lewisite (L1). The non-woven backing laminated to a chemically high-performance ATG film provides superior mechanical strength. ULM II stands out for its superior resistance to bending under thermal pressure, to tearing and for the strength of its seams.

In addition to the quality of the material, the seams, visor and zipper of the suit offer optimum chemical resistance, guaranteeing uniform protection throughout. The entire suit is distinguished by its exceptional performance, a major asset. The seams are reinforced and sealed by thermoplastic welding for enhanced durability.

- Semi-rigid panoramic screen

Thanks to its panoramic, semi-rigid PMMA screen, the worker benefits from maximum, undistorted visibility, essential for operations in hostile environments. What's more, the visor is equipped with a tear-off, an additional chemical protection film applied to the screen to protect against chemical splashes and mechanical aggression. This equipment is easily replaceable when the operator carries out inspection or maintenance of the garment after intervention.

- Quick and easy maintenance

ULM II, a chemical combination of normal robustness, offers a 10-year service life with a compulsory annual inspection. The inspection is visual, and requires no maintenance if the suit has no major apparent defects. After 5 years of ownership, a complete re-qualification is carried out to extend its use for a further 5 years. To ensure protection and simplify transport, the suit is stored in an airtight bag and a dedicated carry bag.

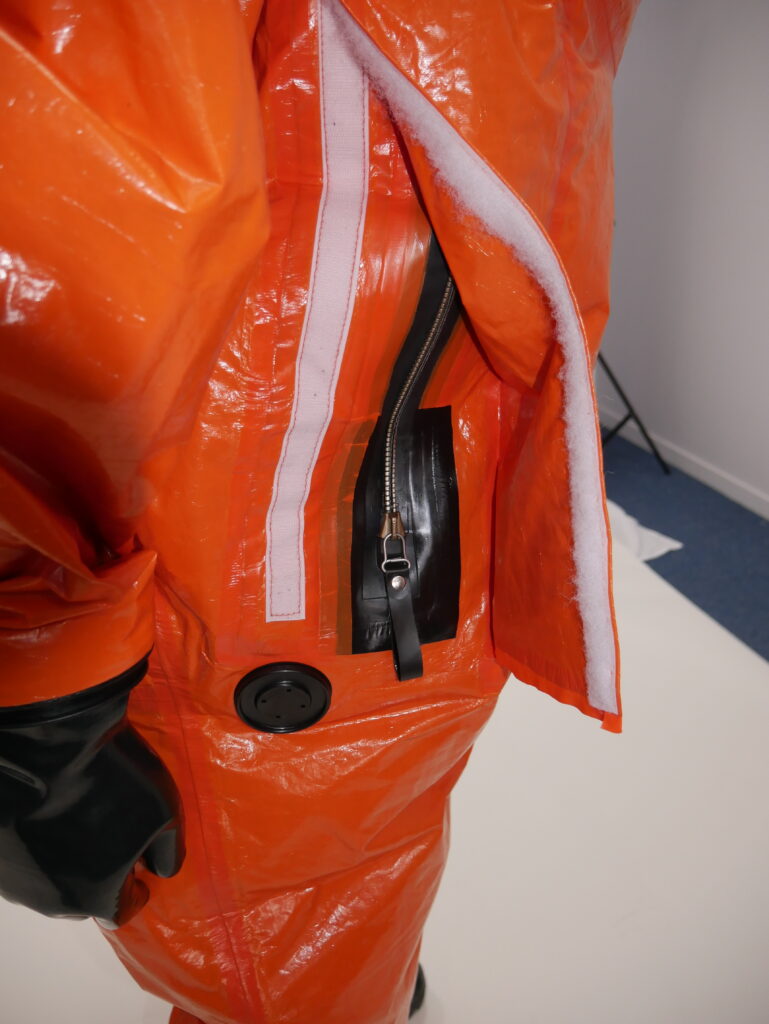

- A new, unique control system

A new feature for the ULM II is the leak-testing system developed by MATISEC. It enables both the company and the (trained) operator to test the suit's entire watertightness, without having to go through one of the garment's extremities.

- A wide range of accessories

Depending on the customer's use and requirements, there are a number of accessories that can be combined with the ULM II. Some of the accessories available: watertight passage, radio loop, tool rings, viewing device for smartphones or cameras. It's important to note that ULM II accessories are just as important as the outfit itself. They ensure a successful user experience. All our customers can obtain the appropriate fittings from MATISEC and install them themselves. In our discussions with customers, we make sure we take into account all the issues, challenges and suitable accessories to best meet their needs and expectations.

Our customers use ULM II

One of our customers is in charge of dismantling chemical warfare weapons containing arsenic and other types of toxic warfare agents. In the event of failure of the robots and other automated machines in charge of detonating a bomb, the operators intervene in chemical suits to take over. This customer equips its personnel with ULM II and ARI MATISEC for this type of intervention.

To see the ULM II product page, click on the button below!

Don't hesitate to visit our blog to follow MATISEC news and learn more about the company.

You can also find us here!

News & Events

2024 retrospective: TOP 5 events of 2024

Ocenco, our sole shareholder, pays us a visit